ABOUT US

Breakthrough

Sunwin

INTRODUCTION

Taizhou Huangyan Sunwin Mould Co., Ltd. is located Huangyan, Zhejiang Province and called the city of plastics and mold. We have more than 2000 square metres covers and 60 prodessional mould manufacturers, we have professional equipments, high speed CNC, EDM, WEDM, Carving, driller, Grinder, Conventional Milling CNC Machining Center. We have many high technical engineers to design mould, Using CATIA, AutoCAD design software, at the beginning of mould design, we use of Moldflow software to analysis first, optimize the structure of mould and gate type. Our superiority is not only producing precision mould, but supplying rapid high-efficient technique support and equipping with the relevant to give the best solutions for our customer.

-

-Founded in 2010

-

-m²Factory Area

-

-+Enterprise employees

-

-+Annual output

products

Innovation

NEWS

Service First

-

What are the common defects in injection molding of automobile bumper products?①

The application of automotive plastic parts has significant advantages in reducing vehicle quality, saving fuel, promoting environmental protection, and being recyclable. Most automotive plastic parts are injection molded. Tiger skin patterns, poor surface reproduction, sink marks, weld lines, wa...

-

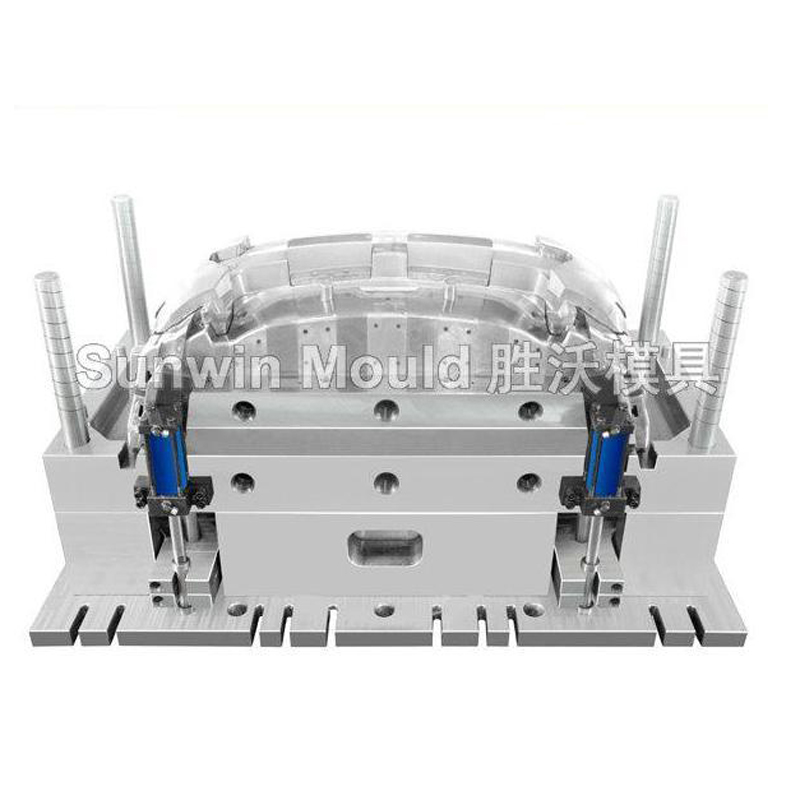

Automotive Handle Mould

The gas-assisted process is a relatively complicated process. In general, the product is filled first, then the high-pressure inert gas is blown, the raw material in a semi-molten state is blown out, and the gas is used instead of the injection molding machine to obtain the product. Become a gas-...