Products

-

SMC Compression Mould

Sunwin Mould is a professional composite molds manufacturer, we produce various glass fiber composite molds, SMC, BMC, GMT, LFT-D, HP-RTM, CFRP, RTM mould carbon fiber composite molds.

-

Plastic Crate Mould

We have rich experience in crate mould manufacture, we have made single point cold runner and multipoint hot runner for our customer, we hope to make 5 point gate hot runner for you, theadvantage of multipoint hot runner: Reducing injection pressure and fast fill the cavity, increase theusing life of mould. Shorten the cycle time, improve the production efficiency, you may send us thesample, we may design first, then use mold flow software to analyze the best location of gate.

-

Automotive Center Storage Box Mould

Sunwinmold manufacturers a serials of automotive mould including: HVAC mould, bumper mould, auto lamp mould and automotive exterior/interior mould.

Taizhou Huangyan sunwin Mould Co., Ltd. is famous China Automotive Mould Manufacturers and Automotive Mould company which specialized in designing and making Automotive Mould. We own a state of the QC lab and injection workshop and Automotive Mould factory, advanced CNC equipment and experienced R&D team.Engineering work includes not only mold designs, but also mold feasibility, mold flow, product design expertise and prototyping services.

It can be said that the rapid development of the plastic mold manufacturing industry is mainly due to the innovation of CNC milling technology. From traditional milling machines to three-axis machining centers, to today’s five-axis high-speed milling, The processing of three-dimensional surface parts that can be complicated is almost always a reality, and the hardness of the material is no longer a limitation. The main cavity and profile of the plastic mold are completed by CNC milling.

-

Automotive Low Pressure Injection Mould

Automotive Low Pressure Injection Mould The warp-knitted fabric can be stretched without deformation and sharp edges and corners. First, the characteristics of warp knitted fabric injection molding 1. The warp knitted fabric layer is a hot-melt composite process. Due to the compression of the mold and the extrusion of the molten plastic; the longitudinal and lateral extension of the fabric will be different. The most prominent problems are: seepage, breakdown and damage. 2. Flowability o... -

Automotive Instrument Panel Mold

Sunwin mold has developed the automotive Interior moulds for international automotive OEM brands. We offer car Interior molding with excellent quality and short delivery.

For Interior mold tooling, high precision is very important. Such as door trims products have high requirements on the appearance. We also make dashboard mould, door inner panel mould, AB boss mould.

Usually, door trim will be requested for texture. On the product, it can not appear welding line, ejector white mark, shrinkage mark, and deformation. And we DG MOULD have rich experience in making these moulds,we know how to make the best design for them. And below is the regular specification for car door trim mould.

-

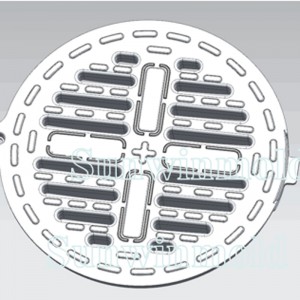

Automotive Grille Mould

Sunwinmould supplied many type auto Grille mould, Auto bumper mould and auto bumper bracket mould.

In order to meet the demand of outer looking auto grille mold, Sunwinmould produced a specular injection mould adopting an electrical heating way.

1. Structure of inner departing surface: Sunwinmold can master the structure and set the departing line on the non exterior surface to be ejected, so it will avoid small step on the surface of auto bumper and avoid the issue of cutting flash. At finally, it helps to realize the smooth surface of auto bumper.

2. The location of injection gate: The reasonable allocation of injection gate could reduce the pressure difference of cavity, it directly affects the quality of auto bumper.

3. The location of taking injection part: Leave the injection part on cavity side or core side? We have to consider the reasonable structure of auto bumper mould ejection system.

-

Automotive Plastic Grille Mould

Sunwinmould supplied many type auto Grille mould, Auto bumper mould and auto bumper clip mould.

IN order to meet the demand of outer looking auto grille mold, Sunwinmold always Activa in improving the technology in automotive grille mould.

1. Structure of inner departing surface: Sunwinmold can master the structure and set the departing line on the non exterior surface to be ejected, so it will avoid small step on the surface of auto bumper and avoid the issue of cutting flash. At finally, it helps to realize the smooth surface of auto bumper.

2. The location of injection gate: The reasonable allocation of injection gate could reduce the pressure difference of cavity, it directly affects the quality of auto bumper.

3. The location of taking injection part: Leave the injection part on cavity side or core side? We have to consider the reasonable structure of auto bumper mould ejection system.

-

Automotive Plastic Grille Mould

Sunwinmould supplied many type auto Grille mould, Auto bumper mould and auto bumper clip mould.

IN order to meet the demand of outer looking auto grille mold, Sunwinmold always Activa in improving the technology in automotive grille mould.

1. Structure of inner departing surface: Sunwinmold can master the structure and set the departing line on the non exterior surface to be ejected, so it will avoid small step on the surface of auto bumper and avoid the issue of cutting flash. At finally, it helps to realize the smooth surface of auto bumper.

2. The location of injection gate: The reasonable allocation of injection gate could reduce the pressure difference of cavity, it directly affects the quality of auto bumper.

3. The location of taking injection part: Leave the injection part on cavity side or core side? We have to consider the reasonable structure of auto bumper mould ejection system.

-

High Gloss Mould

Sunwinmould supplied many type auto Grille mould, Auto bumper mould and auto bumper clip mould.

IN order to meet the demand of outer looking auto grille mold, Sunwinmold always Activa in improving the technology in automotive grille mould.

1. Structure of inner departing surface: Sunwinmold can master the structure and set the departing line on the non exterior surface to be ejected, so it will avoid small step on the surface of auto bumper and avoid the issue of cutting flash. At finally, it helps to realize the smooth surface of auto bumper.

2. The location of injection gate: The reasonable allocation of injection gate could reduce the pressure difference of cavity, it directly affects the quality of auto bumper.

3. The location of taking injection part: Leave the injection part on cavity side or core side? We have to consider the reasonable structure of auto bumper mould ejection system.

-

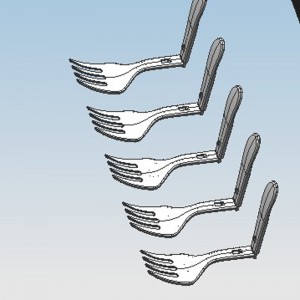

Plastic Spoon Mould

Sunwinmold produced good quality spoon mould, stacking spoon mould, disposable spoon mould and so on. Sunwin designs and develops product according the requirements of customers. we control mould quality and date of delivery. We could manufacture cold runner mold and hot runner mold, and 16 cavities to 48 cavities according the specifications of the product and injection molding machine.

Sunwin Mould is China professional cutlery moulds manufacturer.

Thanks for visiting Sunwin Mould — fork mould, plastic fork mould.

-

Plastic Fork Mould

Foldable cutlery allows the consumption of yogurt, ice cream, jelly, salad, noodles, porridge and other foods on the go. Dessert PP foldable spoon can be used for sweet, foldable dessert spoon is very practical. And the most important is the folding design, the spoon can be placed in the lunch box, that doesn’t account for space, so foldable spoon will not only convenient for you but also give you a safe food experience.

As a skilled plastic injection mould company, Sunwin shows you the process of making foldable cutlery mould, folding spork mould and foldable fork mould.

-

Plastic Dog House Mould

Hot Sale Household Top Quality Pet House Injection Mould/ Dog Cat Cage Injection Mould/ Pet Transport Cage Mould Equipment FAQ Q: Do you make molds for many plastic pets mould? A: Yes, we make Pet House Injection Mould/ Dog Cat Cage Injection Mould/ Pet Transport Cage Mould Q: Do you have injection molding machines to produce parts? A: Yes, we have our own injection workshop, so we can produce and assemble ...